Thermodynamic Proficiency Testing

NAPT’s Thermodynamic Proficiency Testing programs help labs demonstrate competence, meet accreditation standards, and strengthen quality control across high-stakes industries.

What Is Thermodynamic Proficiency Testing?

Thermodynamic proficiency testing is the process of assessing a laboratory’s ability to accurately measure thermal quantities—such as temperature, humidity, and heat flow—using traceable artifacts.

The Impact of PT Testing

Why It Matters

Accurate thermodynamic measurements are essential for product safety, process control, and energy efficiency. Even small deviations can lead to costly rework, compliance issues, or compromised product quality.

Participating in thermodynamic proficiency testing helps your lab:

- Maintain ISO/IEC 17025 accreditation and compliance standards

- Detect out-of-tolerance instruments or techniques to ensure reliable measurements

- Support internal quality assurance and quality control programs

- Increase customer trust and operational credibility through accurate calibration

Driving Industry Precision

Industries That Rely on Thermodynamic Testing

Thermodynamic proficiency testing supports accuracy and consistency across a wide range of industries where precise thermal measurements directly affect performance, safety, and compliance.

- Aerospace & Defense — Ensuring high-precision temperature and humidity measurements for flight-critical components

- Medical Device Manufacturing — Supporting FDA and ISO precision standards for labs, controlled environments, and medical instruments

- Automotive & Energy Systems — Validating temperature sensors, battery thermal management, and industrial process control

- Electronics & Semiconductor — Maintaining precise thermal conditions for sensitive components

- Industrial & General Manufacturing — Standardizing thermal processes and instrumentation across facilities

Available Thermodynamic

Testing Kits

NAPT offers a comprehensive catalog of thermodynamic proficiency testing kits, including:

Low and high temperature calibration (-10 °C to 400 °C)

Chamber or saturated salt solution calibration for (10–98) RH% at (15 to 25) °C

Precision temperature measurement (-196 °C to 420 °C)

Low- and high-temperature thermocouple validation

Accuracy testing across standard temperature ranges

Validate non-contact temperature measurement capabilities (-20 to 750) °C, wavelength (8-14) µm

High-precision thermistor calibration

Validate temperature input and 4–20 mA output for automated systems

How The Process Works

Request a Kit

Receive and Measure

Submit Results

Review Report

Take Action

Featured Thermodynamic Testing Kits

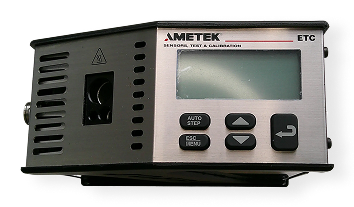

Resistance Temperature Detector

The intent of this ILC/PT is to give organizations an opportunity to evaluate their practices, training, and measurement uncertainty in the calibration of a RTD (Resistance Temperature Detector). This ILC/PT Kit contains a RTD Probe and Digital Readout Device with 0.01C resolution.

View Available KitsHigh Temperature Dry Block

The intent of this ILC/PT is to provide a means for the participant to determine the appropriateness and effectiveness of participant practices, training, and measurement uncertainty relating to testing and calibration of Dry Block Temperature Sources.

Find a Thermodynamic Testing Kit